The Ultimate Overview to Putting Up Hot Mix Asphalt

Warm Mix Asphalt installment is an exact procedure that demands attention to detail and adherence to specific standards to attain ideal outcomes. From preliminary site prep work to the last touches, each action plays a vital function in guaranteeing the resilience and efficiency of the asphalt sidewalk. Comprehending the complexities of Hot Mix Asphalt installment can cause economical services and resilient infrastructure. Join us as we browse with the important actions and upkeep techniques that add to an effective asphalt project.

Understanding Hot Mix Asphalt

Hot Mix Asphalt, generally referred to as asphalt concrete, is a flexible material made use of in road construction and upkeep - hot mix asphalt. It is made by integrating mineral accumulation like sand, crushed rock, or smashed stone with liquid asphalt, a petroleum product obtained from unrefined oil. This mixture is heated and afterwards compacted to produce a long-lasting and durable surface area for roads, parking area, and driveways

One secret benefit of Warm Mix Asphalt is its ability to endure heavy tons and extreme weather. Its versatility allows it to increase and acquire with changing temperature levels, lowering the likelihood of pockets and splits developing gradually. In Addition, Warm Mix Asphalt can be personalized to satisfy particular job demands, such as varying traffic volumes or environmental factors to consider.

Correct setup and maintenance of Hot Mix Asphalt are essential to ensure its long life and efficiency. This consists of suitable site prep work, proper blending and compaction methods, and regular repairs when required. By comprehending the attributes and benefits of Hot Mix Asphalt, project supervisors and service providers can make educated decisions to attain effective road construction tasks.

Site Preparation and Clearing Up

To guarantee the effective setup of Warm Mix Asphalt, the initial action entails detailed website prep work and cleaning to develop a suitable structure for the sidewalk. Site prep work is crucial as it sets the phase for a durable and resilient asphalt surface area.

Following cleaning, the website must be correctly rated to develop the desired incline and surface area degree for water runoff. Grading likewise aids in achieving the needed density and harmony of the asphalt layer. Compaction of the subgrade is then lugged out to enhance stability and stop resolving gradually. It is vital to compact the subgrade evenly to stay clear of uneven settling that might cause splits in the asphalt later.

Along with these actions, any type of utility modifications or installments ought to be finished prior to continuing to the following stage of blending and using the asphalt. Correct website prep work is fundamental to the overall quality and long life of the Warm Mix Asphalt pavement.

Mixing and Applying the Asphalt

Upon completion of website preparation and cleaning, the following vital phase in setting up Hot Mix Asphalt includes the thorough procedure of applying the asphalt and mixing mixture. The blending of warm mix asphalt is commonly carried out at heats to ensure proper binding of the materials. The asphalt combination is created by mixing warm asphalt binder with accumulated products such as sand, gravel, or crushed stone. This procedure requires precision to attain the proper proportions and uniformity for optimal efficiency.

Once the asphalt combination is prepared, it regrading is delivered to the paving site using trucks particularly created to keep the combination hot. The application of hot mix asphalt is done utilizing heavy equipment like pavers and compactors. The paver disperses the hot asphalt mixture equally across the ready surface, while the compactor after that compresses the combination to accomplish the wanted density and level of smoothness.

Appropriate mixing and application of hot mix asphalt are essential for the longevity and durability of the smooth surface. Cautious attention to detail during this stage makes sure a premium completed product that can hold up against the rigors of web traffic and the elements.

Compaction and Finishing Touches

After the warm mix asphalt has been equally distributed by the paver, the next essential step is to make sure proper compaction and apply completing touches to the smooth surface. Compaction is necessary to accomplish the desired durability and durability of the asphalt sidewalk. This procedure includes making use of a heavy roller to compress the asphalt blend, getting rid of air voids and making sure a limited bond between the specific particles. Correct compaction likewise assists in avoiding water infiltration and maintaining the structural stability of the sidewalk.

Completing touches are the last actions required to refine the surface area of the asphalt. This might include dealing with any abnormalities, smoothing out harsh areas, and ensuring correct drainage to stop water buildup. Depending upon the job specs, a last layer of sealer or top covering might be put on enhance the look and shield the asphalt from wear and tear.

Attention to detail throughout compaction and completing touches is vital in accomplishing a top quality asphalt sidewalk that will certainly withstand the examination of time.

Maintenance Tips for Durability

Implementing a proactive upkeep plan is important for making certain the long-lasting toughness and efficiency of hot mix asphalt sidewalks. Regular examinations of the asphalt surface ought to be conducted to recognize any kind of indicators of wear, splitting, or gaps. Trigger fixings of these concerns can stop more damage and lengthen the life-span of the sidewalk.

One important aspect of maintenance is maintaining the surface totally free and tidy of debris. Normal sweeping and cleansing can avoid the build-up of materials that can deteriorate the asphalt over time. Furthermore, appropriate water drainage should be preserved to protect against water from merging externally, as standing water can leak into the asphalt and create degeneration.

Sealcoating is another crucial maintenance task that must be carried out periodically. This protective layer aids to secure the asphalt from harmful UV rays, water penetration, and automotive fluids, prolonging its lifespan substantially. By complying with these maintenance ideas carefully, you can make certain that your warm mix asphalt pavement remains in top problem for many years to come.

Conclusion

Finally, the procedure of installing Hot Mix Asphalt is important for developing resilient and long-lasting roadway surface areas. Appropriate site prep work, precise blending and application, compaction, and finishing touches are crucial actions in making sure the high quality and longevity of the asphalt pavement. Routine upkeep, including inspections, repair work, cleansing, and sealcoating, is vital to protecting the integrity of the asphalt and maximizing its performance in time.

Hot Mix Asphalt, typically known as asphalt concrete, is a versatile product utilized in road construction and maintenance.To guarantee the effective installment of Hot Mix Asphalt, the first step includes comprehensive site prep work and clearing to create an ideal structure for the pavement (hot mix asphalt).Upon completion of site preparation and clearing, the following essential stage in mounting Hot Mix Asphalt entails the meticulous procedure of using the asphalt and mixing combination. The mixing of hot mix asphalt is typically carried out at high temperature levels to guarantee correct binding of the products. The asphalt combination is produced by mixing hot asphalt binder with accumulated products such as sand, crushed rock, or smashed rock

Mr. T Then & Now!

Mr. T Then & Now! Neve Campbell Then & Now!

Neve Campbell Then & Now! Alana "Honey Boo Boo" Thompson Then & Now!

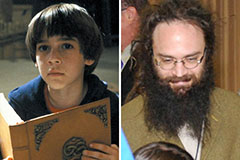

Alana "Honey Boo Boo" Thompson Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now!